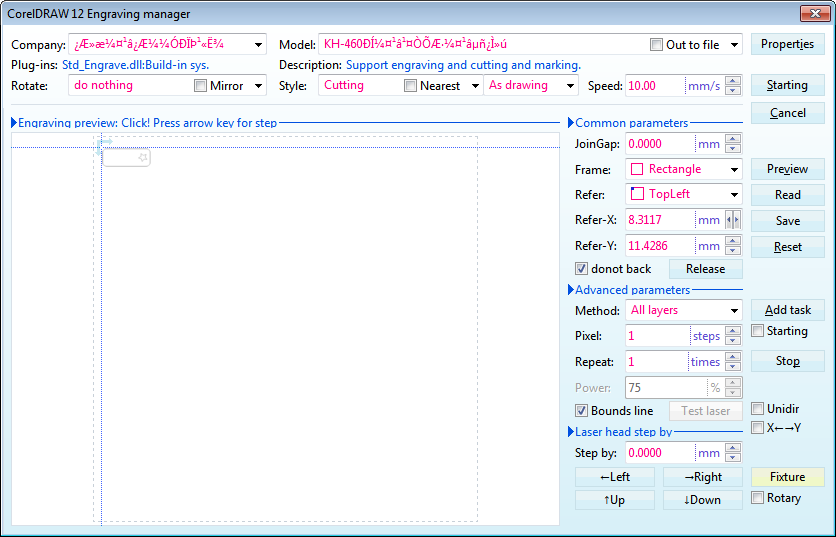

Dadurch wird das Gerät auf ttyUSB0 gemappt und eine Kommunikation über K40 Whisperer ist nicht mehr möglich. Wenn man den Laser einschaltet, läd Linux automatisch das Treiber-Modul des CH341. A lot of people say yhat replacing the USB cable fixes the problem for them Der CH341 ist der USB/Seriell Wandler Chip auf dem M2nano Board des K40 Laser. K40 Whisperer tries to get a response from the controller board but sometimes it just won't respond without a reset. Something caused the controller board in the laser engraver to stop responding. If it works using sudo then it is definitely a permissions issue usb timeout - K40 Forum - AwesomeTec Try running K40 Whisperer using sudo (or as root). If you are running Linux you might not have given yourself the correct permissions to access the USB port/device. What Causes USB Error, Laser USB Device not Found error? Your laser might not be turned on. Installing the Mini Gerbil MiniGerbil Troubleshooting Guide Mini Gerbil debugging - homing operation Gerbils Alarm, error and option codes What are $ Settings ? Downloads Super Gerbil Hardware Installation PPA $ 0.00 0 item It seems that Laser Draw (LaserDRW) is less sensitive to the timeout issue so there is probably some improvements that could be made to K40 Whisperer. You need to find your optimal combo.K40 controller review K40 laser grounding instructions K40 Forum. Test similar design to learn how power and speed relates on your machine, this is different on most K40 and you cannot use the same settings someone else has. Pixel: set this to 1 step, and Repeat to 1 times In the template before, we split engraving and cut in two different layers, this will help you to run the engraving first, and cut later. Method: If you have combined engraving and cut in the same file, you can choose here. I would suggest 12mA power and 10mm/sec to start with. Speed: I have a 3mm acrylic piece in my machine, you may have to test the speed and the power on your machine when testing your cut. Inside first is a good option if you make parts, the machine will cut the inner parts first and then the outer, preventing the part to fall down without the inner holes are cut. Rotate: if you need to rotate or flip your design for mirrored cut/engravings. Now you have this setup box (click to expand)Ĭompany and model is just the data about your machine. Select CUT in the corel menu, the icon marked hereĬlick OK on the data setting, we did this in a earlier step. You are now ready for your first cut test. Select the box as shown in the picture, and in the top menu you see a line width set to “hairline”. Start with the “rectangle tool” in corel, make a box with the size of your choise, i made a 54x40mm box. You are now ready to start your first test with the machine

Next setting is to check your hardware device ID, you can find this on the controller board, se image belowĬheck out the other settings and make sure you have the same on your settings. You can find information about wich board you have on the controller board in your machine. Most important setting is the mainboard, you may need to change this later if your machine operates very slow (a first sign of wrong mainboard selected) When CorelLaser is installed you will find this menu.Ĭontrol your settings so its identical to this screen. You can use this template to start with, it has one engraving layer and one cutting layer.

Setting up laserdrw 3 install#

Step 1: Install Corel Draw 12, X4, X8 or similar version.

0 kommentar(er)

0 kommentar(er)